Plastic Molding Automation

Robots, handling devices, and control systems can operate around the clock in an exact and reproducible rhythm, and at extremely high speeds. REO’s innovative plastic molding automation engineers design and operate automation processes optimized to streamline your process flow.

- Increase productivity

- Reduce costs

- Improve quality and consistency

Plastic Materials

Our wide range of available plastic materials can support nearly any application. If you don’t see the material you need, talk to one of our specialists.

- Acetal (Acetal)

- Polycarbonate (PC)

- Polypropylene (PP)

- Acrylic (Acrylic)

- Polyester (Polyester)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyether Imide (PEI)

- Polysulfone (PSU)

- Biodegradable Polymers (Biodeg Polymers)

- Polyetherketone (PEK)

- Polyurethane (PUR)

- Cellulose Acetate (CA)

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Polyamide (Nylon)

- Polyimide (PI)

- Styrene Acrylonitrile (SAN)

- Polyarylate (Polyarylate)

- Polyolefin (Polyolefin)

- Thermoplastic Elastomer (TPE)

- Polybutylene (PB)

- Polyphenylene Sulfide (PPS)

- Thermoplastic Polyurethane (TPU)

Plastic Equipment

We have a wide variety of plastic equipment and in-house capabilities to streamline any process. Explore our full facilities list.

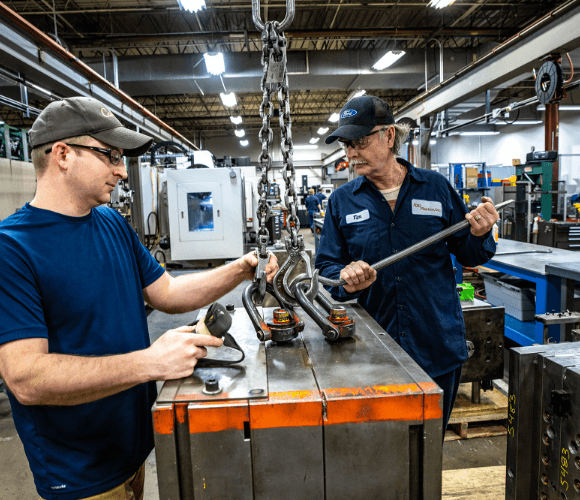

Plastic Tooling

Our robust toolroom and experienced toolmakers can support and maintain our client’s tools. Our plastic tooling specialists can work with inherited tooling or build your tools from scratch.

- Project management of tool construction

- Fully equipped tool room

- Domestic and overseas tool sourcing availability

- Computer-aided manufacturing

- CNC milling and EDM machines

- Extensive tool maintenance program

- Short lead times/Speed to market

- Experienced mold makers available 24 hours

Plastic Engineering

Our plastic engineering and design services provide our customers with creative ingenuity and highly skilled manufacturing and engineering expertise to achieve the speed to market they deserve. Our engineers work with you from conception through production and develop the ultimate process optimization for complete program success.

- Product Development Services

- Design Engineering

- Technological Innovation

- Design for Manufacturability/Assembly

- Material Selection Assistance

- Mold Flow Analysis

- Prototype to Production Manufacturing

- Tooling and Fixture Build

- Assembly and Verification Testing

- Multiple Engineering Software

- Robotics and Automation

- Cost Savings Ideas/Recommendations